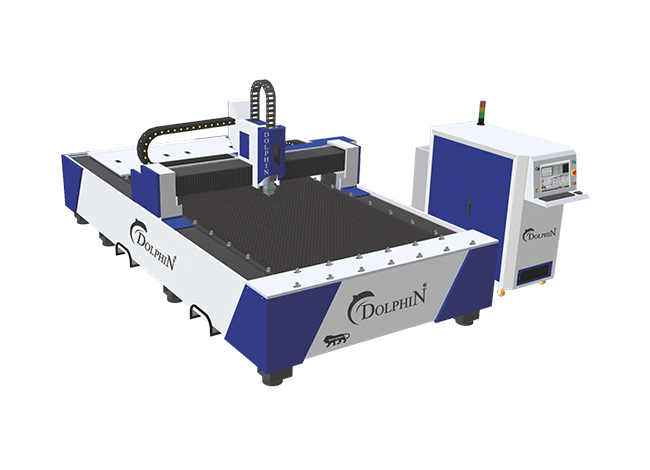

The manufacturing industry is evolving rapidly, and advanced cutting technologies are at the center of this change. A Fiber Laser Cutting Machine has become a preferred solution for industries that demand accuracy, speed, and consistent quality. From metal fabrication to automotive production, this technology is redefining how materials are processed. Laser Machine Manufacturers continue to innovate in this space to meet growing industrial expectations and global production standards.

As competition increases, companies seek equipment that improves output while lowering operational costs. Fiber laser systems answer this need by delivering precise cuts, reduced waste, and reliable performance across diverse applications.

Fiber Laser Cutting Machine and Its Core Technology

At the heart of this innovation lies advanced laser source technology that produces a high-intensity beam capable of cutting through metals with exceptional precision. Within a Fiber Laser Cutting Machine, the laser beam is generated through optical fibers, which improves energy efficiency and beam stability. This method allows smoother edges and cleaner cuts compared to traditional cutting systems.

Laser Machine Manufacturers design these machines to handle stainless steel, mild steel, aluminum, copper, and brass with minimal distortion. As a result, manufacturers can achieve uniform results even during continuous operations.

Fiber Laser Cutting Machine Enhancing Production Efficiency

Manufacturing efficiency depends on speed, accuracy, and minimal downtime. A Fiber Laser Cutting Machine significantly improves production flow by offering faster cutting speeds and reduced setup time. Unlike conventional cutting tools, fiber lasers require less maintenance, which keeps machines running longer without interruption.

Laser Machine Manufacturers focus on automation compatibility, enabling seamless integration with CNC systems and robotic handling units. This automation reduces manual intervention, increases throughput, and ensures consistent quality across large production batches.

Fiber Laser Cutting Machine for Diverse Industrial Applications

Industrial versatility is another key advantage of this technology. A Fiber Laser Cutting Machine is widely used in sectors such as automotive, aerospace, electronics, construction, and heavy engineering. Each industry benefits from the machine’s ability to process complex shapes and intricate designs with precision.

Laser Machine Manufacturers develop customized configurations to suit specific production needs, whether for thin sheet metal or thick industrial components. This adaptability allows businesses to respond quickly to changing market demands.

Fiber Laser Cutting Machine Supporting Cost-Effective Operations

Cost efficiency is a major consideration for modern industries. While the initial investment may appear significant, a Fiber Laser Cutting Machine delivers long-term savings through reduced energy consumption and minimal consumable requirements. Fiber laser systems are known for their high electrical efficiency, converting more power into usable cutting energy.

Laser Machine Manufacturers optimize machine design to reduce operational expenses while maintaining cutting accuracy. Lower maintenance costs and longer service life further enhance return on investment for manufacturing businesses.

Fiber Laser Cutting Machine and Precision Quality Standards

Precision is critical in industries where even minor errors can lead to costly rework. A Fiber Laser Cutting Machine offers micron-level accuracy, ensuring that every cut meets strict quality specifications. This level of precision improves component fit and reduces material waste.

Laser Machine Manufacturers implement advanced control software and real-time monitoring systems to maintain consistent performance. These features allow operators to adjust parameters quickly and achieve optimal cutting results for different materials.

Fiber Laser Cutting Machine Emphasizing Energy Efficiency

Sustainable manufacturing practices are becoming essential worldwide. A Fiber Laser Cutting Machine supports energy-efficient production by consuming less power compared to older laser technologies. Efficient heat management and optimized beam delivery reduce energy loss during operation.

Laser Machine Manufacturers prioritize eco-friendly designs that align with global sustainability goals. By lowering energy consumption and minimizing waste, fiber laser systems help industries reduce their environmental footprint without compromising productivity.

Fiber Laser Cutting Machine Improving Workplace Safety

Safety is a critical factor in industrial environments, especially when working with high-power equipment. A Fiber Laser Cutting Machine is equipped with protective enclosures, safety sensors, and emergency stop features that reduce operational risks. These built-in safeguards ensure safe working conditions for operators and technicians.

Laser Machine Manufacturers comply with international safety standards and continuously enhance machine design to prevent accidents. User-friendly interfaces and training support further promote safe and efficient operation on the factory floor.

Fiber Laser Cutting Machine Driving Automation and Smart Manufacturing

Smart manufacturing relies on connected systems and automated processes. A Fiber Laser Cutting Machine integrates easily with Industry 4.0 technologies, enabling real-time data monitoring and predictive maintenance. These features improve decision-making and reduce unexpected downtime.

Laser Machine Manufacturers design machines that support automated loading, unloading, and material handling. This automation not only increases productivity but also ensures consistent output quality across multiple production cycles.

Fiber Laser Cutting Machine Supporting Global Competitiveness

In a competitive global market, manufacturing excellence is essential for business growth. A Fiber Laser Cutting Machine enables companies to meet international quality standards while maintaining high production speeds. This capability strengthens export potential and customer satisfaction.

Laser Machine Manufacturers play a crucial role in delivering reliable solutions that help businesses stay ahead of competitors. Advanced laser cutting technology allows manufacturers to take on complex projects and deliver products with superior finish and accuracy.

Fiber Laser Cutting Machine Shaping the Future of Industry

The future of industrial production depends on precision, efficiency, and sustainability. A Fiber Laser Cutting Machine continues to shape this future by offering advanced capabilities that support innovation across sectors. Continuous research and development ensure that laser systems evolve with changing industrial needs.

Laser Machine Manufacturers remain committed to delivering cutting-edge solutions that empower businesses to grow and adapt. By investing in fiber laser technology, industries secure a competitive advantage and prepare for the next generation of manufacturing challenges.